You can download the PDF file of this page. →

The full report of this survey. →

PRESS RELEASE / EXECUTIVE SUMMARY

The Japan Carbon Fiber Manufacturers Association, October

2022

In 1999, the Japan Carbon Fiber Manufacturers Association (JCMA) has published for the first time “life cycle inventory” (LCI) data for carbon fibers. In the following years, several revisions have been published (2004, 2006 and 2012). Since 2006, these LCI data have been based on actual production data, in contrast with many other published data which are based on model calculations and/or lab scale or pilot scale experimental data.

As the assessment of the environmental impact of materials and processes has gained importance in the past decades, an international standard (ISO 14044) has been established (and has been followed in this survey). A full LCA (life cycle assessment) comprises, next to the definition of the goal and scope of the exercise, three main parts: inventory analysis, impact assessment and interpretation. This study is limited to the life cycle inventory (LCI), but analysis of the inventory results provides information on some relevant impact categories like cumulative energy demand (CED), CO2, NOX and SOX emissions, and hence allows comparison with other published LCA data.

The object of this study (“subsystem” in LCA terminology) is the manufacturing of 1 kilogram of PAN-based, high strength carbon fibers, in the form of 12k (800tex) to 24k (1600tex) tows, having an elastic modulus in the range of 230 to 250 GPa. The survey was conducted under a contract between JCMA and the Industry Information Collaboration Research Center (WIC), which has conducted numerous inventory analyses for the materials industry. The input data for this survey (later called foreground data) are provided to WIC by the three Japanese carbon fiber manufacturing companies (Toray, Mitsubishi Chemical, Teijin), and have been measured during the production, in 2017, of 6994 tons of carbon fibers, representing about 40% of the annual domestic production of this type of carbon fibers in Japan. The data is considered to be representative enough for the major markets for CF, such as aerospace equipment and automobiles.

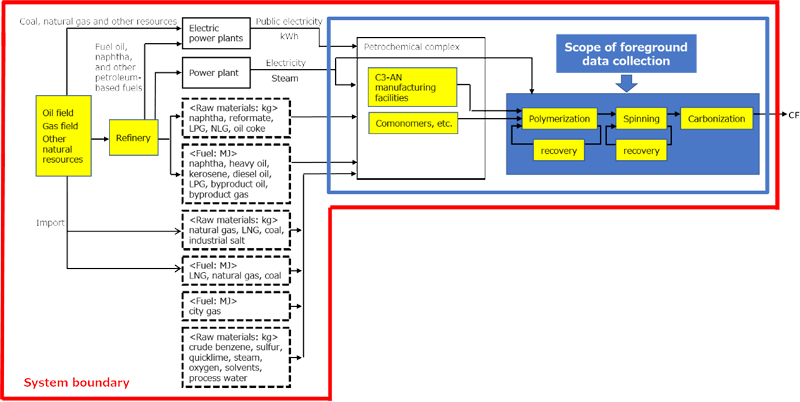

The system boundary is presented in Figure 1. A “cradle to gate” type of calculation has been applied. The foreground data collection has been carried out for the unit process itself, namely the manufacturing of 1 kg of carbon fibers, which consists of three parts: PAN polymerization, fiber spinning and carbonization. For the input of raw materials (acrylonitrile, solvents, …), electricity and steam, retrospective calculations have been carried out (partially based on background data). This finally results in an inventory of cumulative data traced back to natural resources. Further analysis and grouping of these cumulative data allows then to summarize the results of this survey in four relevant inventory categories: CED (cumulative energy demand), CO2, NOX and SOX emissions.

It is believed that this new survey has a unique value for the industrial and scientific community involved in the use and study of carbon fibers (and their composites), because it is based on actual production data. This report should provide sufficient detail for allowing a well-documented comparison with other published LCI (and LCA) data for carbon fibers.

The full report of this survey can be found on

https://www.carbonfiber.gr.jp/english/tech/pdf/lci2022_en.pdf

For further information, please contact JCMA.

https://www.carbonfiber.gr.jp/english/contact/index.html

ACKNOWLEDGEMENT

JCMA would like to

express our deepest gratitude to the following three professors for their hard work in

translating the Japanese full version of the manuscript into clear English and in

preparing this executive summary.

Jun Takahashi, The University of Tokyo (Japan)

Ignaas Verpoest, Katholieke Universiteit Leuven (Belgium)

Véronique Michaud,

EPFL /Ecole Polytechnique Fédérale de Lausanne (Switzerland)